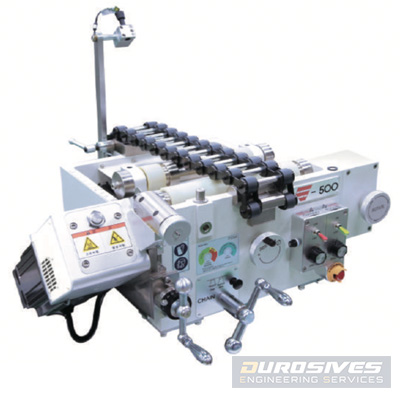

Electric radius chamfering machine

| SPECIFICATIONS | |||

|---|---|---|---|

| Brand | CHAMFO | ||

| Height Adjustment | One-touch spline controller, minimum 0.1mm step | ||

| Usage | Radius bevelling of plate, contour and hole | ||

| Power | 220V/60Hz only | ||

| RPM | Variable speed | ||

| No. of cutters | 1 cutter (8 blades) | ||

| Cutter | CF350C R2, R3, R4, R5 | ||

| Turning base plate | O | ||

| Cutter ejection pins | O | ||

| Spindle lock | O | ||

| Straight guide (option) | available | ||

| Weight | 3kg | ||

Key Features:

- Quick & Easy center setting (One-touch type)

- Turning base plate (Anti-friction)

- Advanced ring type cutter

- Spindle lock for insert(s) replacement

- 3 ejection pins (patented)

- Various Usages (Curves, plates and holes)

Usages:

- Shipbuilding Industry, electricity industry, etc.

[Ref. rule of Shipbuilding Industry]

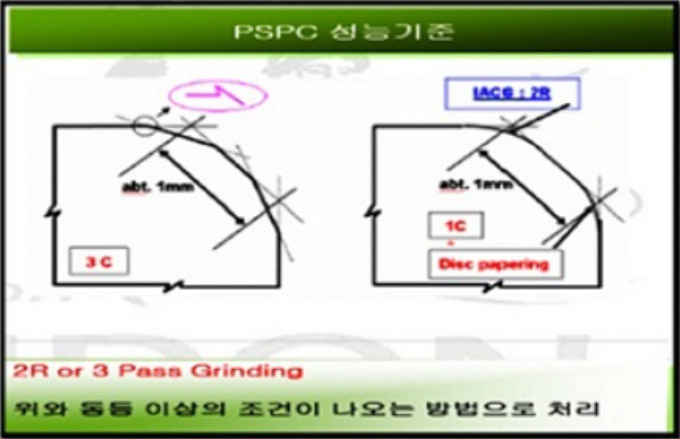

Reference Rule (IMO’s PSPC rule)

- To avoid insufficient coating film thickness at certain areas, such as corners, edges and weld Seams in the ballast tanks, mechanical grinding of the edge area is required since stripe coatings applied on a smoother edge profile will retain liquid paints longer than the sharper shaped edge does

- For this purpose, “3-Pass or 2-R” edge grinding treatment prior to secondary surface preparation is specified by IMO’s PSPC rule

- Full Brochure Download